Services

Our modern service centers provide versatile steel pretreatment services

Our steel service centers and warehouses are located in central locations in Hattula, Uusikaupunki, Akaa and Forssa. Our service centers have approximately 115 employees, an extensive selection of long steel products and steel sheets, as well as versatile pretreatment services.

Our modern equipment and facilities guarantee the best quality in both the treatment and storage of steel products. Our transport network delivers the products to you reliably, professionally and with competitive prices.

Pretreatment services for long products

Pretreatment services for long products

Pretreatment services for long steel products can be found in our Hattula steel service center. Expanded in 2022, 41 000 square meters of production area contain modern equipment and facilities.

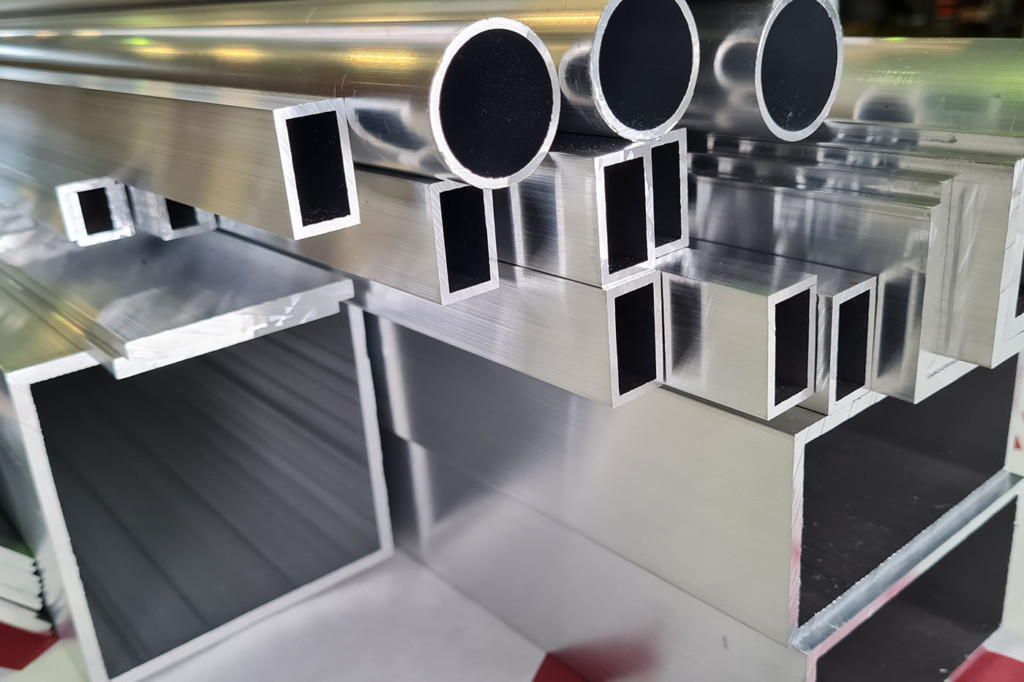

Hattula service center stores and delivers more than 4 000 stock products. In addition, our center serves with versatile pretreatment services for structural and special steels: sawing, centering, drilling and coping, as well as shot blasting and surface treatment.

Cutting services

Steel bars, beams and hollow sections cut to length.

Drilling and coping

Our versatile drilling and coping line finishes beams, tubes and steel bars into ready-made components.

Pre-treatment for round bars and special steel

Cutting, centering and end machining.

Shot blasting and surface treatment

We provide shot blasting and surface treatment.

Pretreatment services for sheet products

Pretreatment services for sheet products

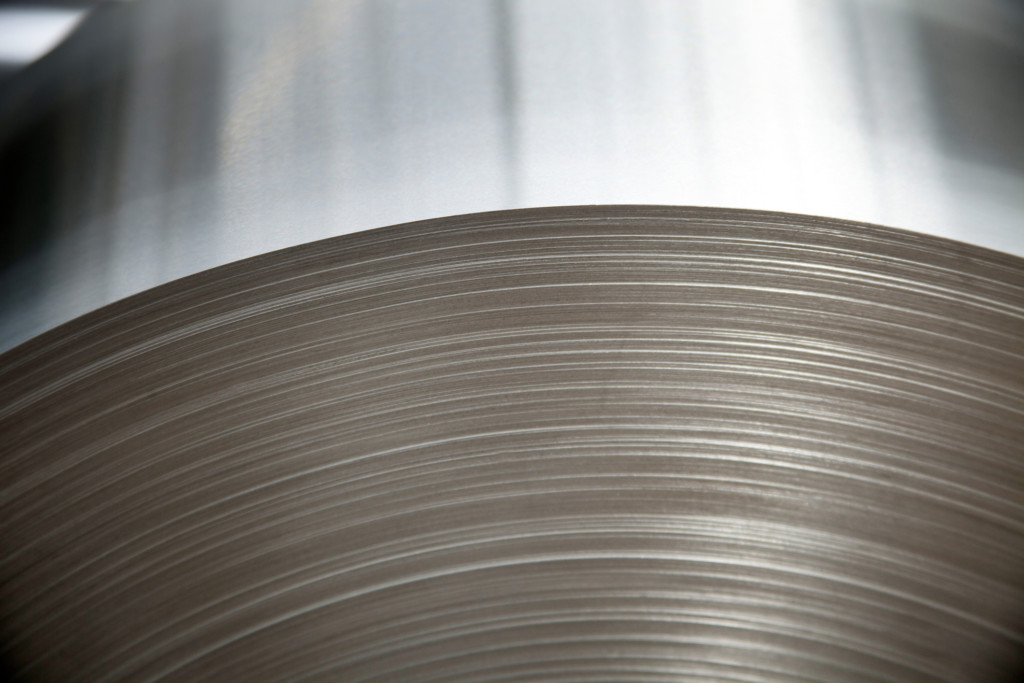

We offer versatile pretreatment services for sheets and plates from laser, plasma and flame cutting to machining and edging. Our service center located in Uusikaupunki harbor area has the largest cut-to-length line in Baltic Sea region: maximum thickness of coils is 20 mm, width 2150 mm and length 15 000 mm.

Cold-rolled, hot-dip-galvanized and electro-galvanized coils in the range of 0,5 – 3 mm thickness are cut-to-length and stored at our service center in Akaa. The maximum width on the cut-to-length line is 1500 mm and maximum length is 4000 mm.

Cutting of hot-rolled steel sheets and plates

We offer hot-rolled steel sheets cut in both standard and custom lengths.

Cutting of cold-rolled sheets

We provide cold rolled, galvanized and other metal coated sheets cut to both standard and custom lengths.

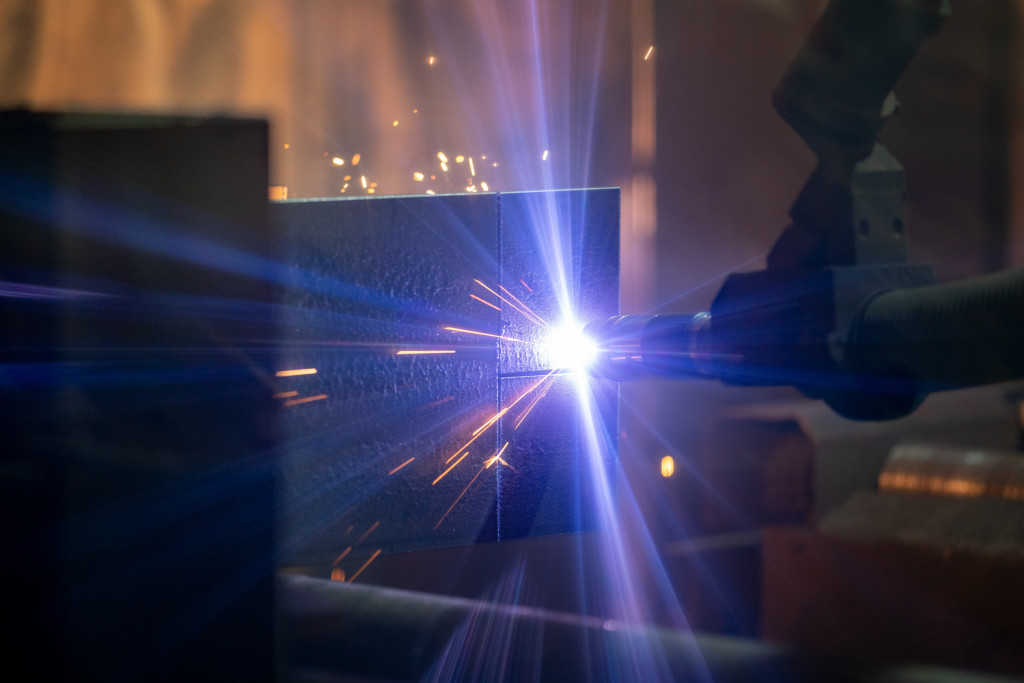

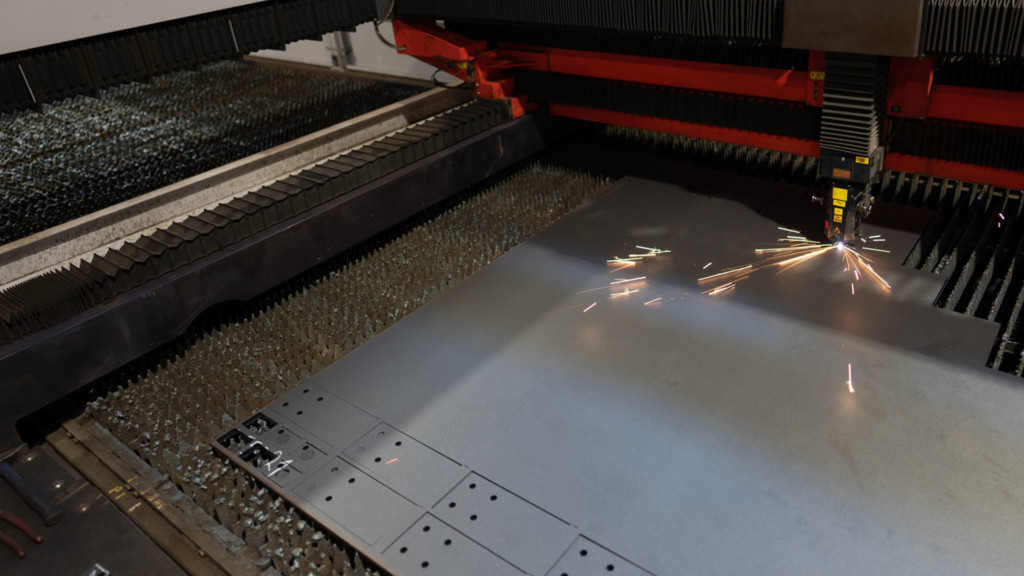

Laser cutting

Our laser cutting service is a cost-efficient way of producing pieces in different shapes and from different materials.

Flame and plasma cutting and bevelling

We provide flame and plasma cutting even for large pieces, and ready-made pieces can be bevelled with our plasma unit.

Edging

We offer edged sheets up to a length of 10 meters from our edging unit, which is one of the most efficient in Finland.

Machining

We offer drilling, threading and coping.

Service Centers

Modern steel service centers and warehouses with central locations

Our steel service centers and warehouses are located in central locations in Hattula, Uusikaupunki, Akaa and Forssa. Our service centers have approximately 115 employees, an extensive selection of long steel products and steel sheets, as well as versatile pretreatment services.

Our modern equipment and facilities guarantee the best quality in both the treatment and storage of steel products. Our transport network delivers the products to you reliably, professionally and with competitive prices, sometimes even on the same day. Our delivery reliability is 97%.

We work constantly to improve the occupational safety, energy-efficiency and carbon-neutrality of our service centers, and our largest service center in Hattula is already fully carbon-neutral. Our aim is to achieve LTI1 frequency level under 5, which we were able to achieve in May 2023 when for the first time in our company history we achieved accident-free year.

Steel Service Center, Hattula

Our Hattula steel service center specializes in long steel products. Hattula provides both structural and round bar steel and building systems for the needs of steel construction and mechanical engineering industries.

The large 41,000 sqm service center stocks more than 4,000 different products. In addition, our center offers a range of pretreatment services: cutting to length, centring, end machining and threading, drilling and coping, and shot blasting and surface treatment.

Our Hattula unit is the most modern steel service center in Finland, with energy-efficient and fully carbon-neutral operations since 2021.

Steel Service Center, Uusikaupunki

Our steel service center in Uusikaupunki offers our range of hot rolled sheets and quarto plates. Sheets are primarily delivered to our service center in coils, and our cutting line straightens them and cuts them to standard or custom lengths.

Uusikaupunki steel service center also provides versatile pretreatment services, from laser, plasma and flame cutting to machining, edging, shot blasting and surface treatment.

The service center is located in the Uusikaupunki port area, and it receives the steel products directly at the port, transferring them to the warehouse.

Aluminium warehouse, Forssa

Building systems, aluminium sheets and other aluminium products by Schüco are available from our 1,200 sqm aluminium warehouse in Forssa. The warehouse serves hundreds of customers, offering fast deliveries. Our paintshop partner is located in the same premises, which means we can deliver painted products quickly and cost-efficiently.

Our highly optimized aluminium storage has had zero occupational accidents since 2015.

Akaa unit

Our Akaa unit provides thin sheet products in thicknesses of 0.5 – 3.0 mm. The largest cut-to-length line in Finland provides sheets cut to both standard and custom lengths. The efficient line and extensive stock of standard steel sheets ensure quick deliveries.